Welcome to our product page, where innovation and excellence meet to transform your identification needs. At Cheef, we take pride in offering a diverse range of top-of-the-line products that cater to your specific requirements.

Our impressive selection includes:

CIJ (Continuous Inkjet) Printers: Harness the power of high-resolution coding with our reliable CIJ printers, designed for versatility and precision across various surfaces.

TTO (Thermal Transfer Overprinting) Printers: Take your coding capabilities to the next level with our advanced TTO printers, delivering exceptional results on flexible packaging materials.

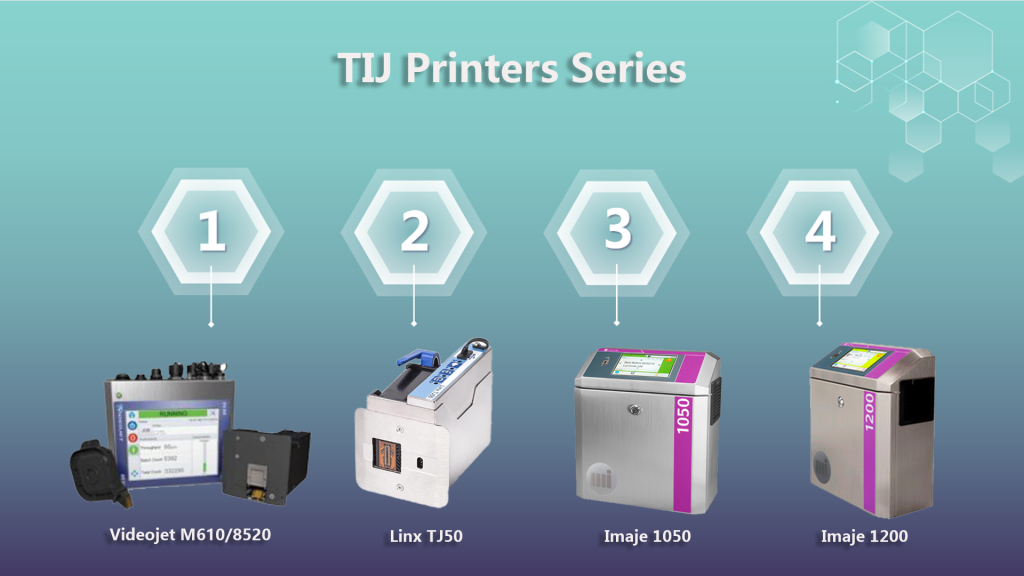

TIJ (Thermal Inkjet) Printers: Enjoy the perfect blend of portability and efficiency with our TIJ printers, ideal for on-the-go coding needs.

DOD (Drop on Demand) Printers: Achieve sharp, clear markings with our DOD printers, perfectly suited for industrial applications requiring precise printing.

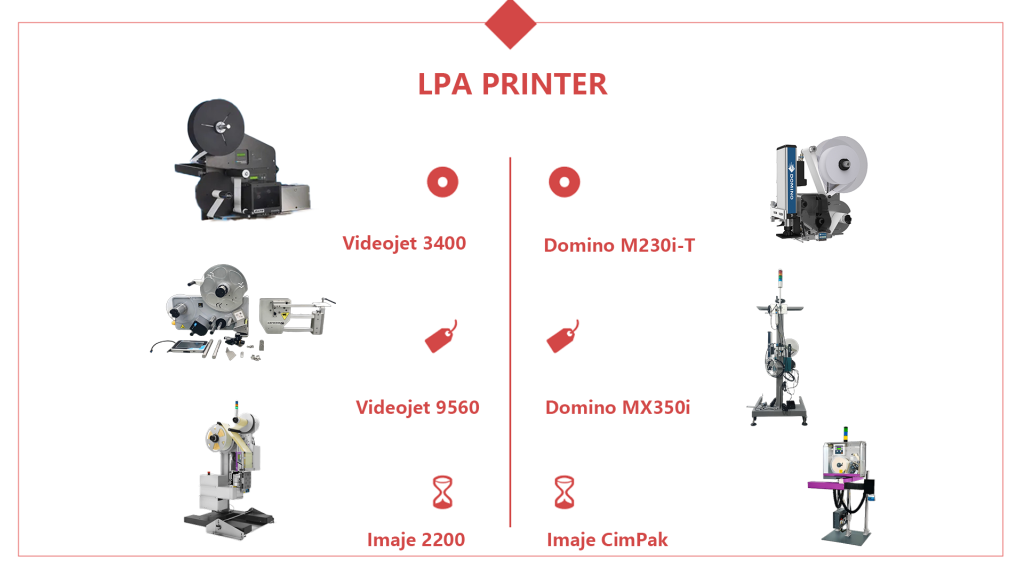

LPA (Large Character Printers): Make a bold impression with our LPA printers, known for their exceptional clarity, durability, and high-performance capabilities.

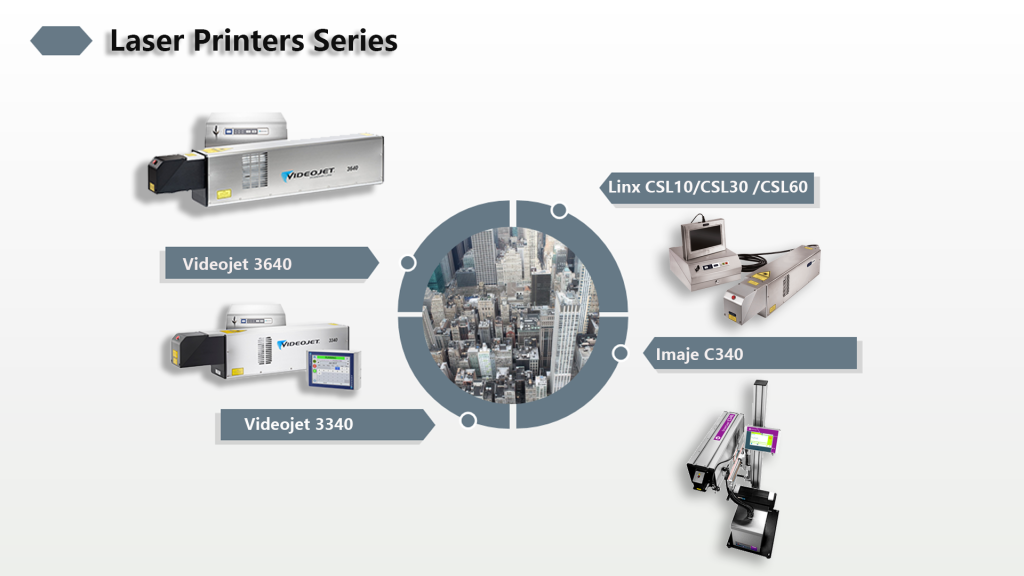

Laser Marking Systems: Experience the highest level of precision with our laser marking machines, providing permanent, high-quality markings on a wide range of substrates.

Second-hand Machines: Offering cost-effective solutions without compromising the quality of your coding operations, our second-hand machines present an excellent opportunity for end customers.

Ink and Ribbons: Our ink and ribbon products are crafted for superior performance and reliability. We ensure the highest quality to meet the demands of various printing applications, ensuring consistent, vibrant, and lasting results. Whether for industrial or commercial use, our inks and ribbons are engineered to optimize your printer’s functionality and provide excellent print clarity.

Global Partner Recruitment: We are actively seeking global agents and partners to expand our reach and bring these innovative solutions to new markets. Join us in offering cutting-edge printing technologies and unparalleled quality to customers worldwide. With a focus on long-term partnerships and mutual growth, we invite you to explore exciting collaboration opportunities with us.

With our extensive expertise in the industry and a keen focus on quality, we take the guesswork out of choosing the right identification solution. Our products are carefully curated to meet the highest standards, ensuring reliable performance and exceptional results.

When it comes to identification solutions, we are the ultimate choice for discerning customers like you. Discover the Cheef difference today and unlock a world of possibilities for your business.

Browse through our product offerings and let us be your trusted partner in elevating your brand with cutting-edge identification solutions. Reach out to us now to explore the right product for your needs and take a step towards transforming your coding operations.

Choose Cheef – Your Final Destination for Excellence in Identification Solutions!

Introducing Small Character Inkjet Printers (CIJ) – The Power of Precision Coding

Small Character Inkjet Printers (CIJ), also known as Continuous Inkjet Printers, are a versatile and essential tool in the world of product identification and coding. These compact yet powerful machines utilize advanced inkjet technology to create clear, concise, and precise codes on various surfaces. CIJ printers are an integral part of industries spanning from food and beverages to pharmaceuticals and manufacturing.

CIJ technology works by propelling tiny droplets of ink onto the target surface at high speed. This process allows for rapid and continuous coding on a range of substrates, including plastics, metals, glass, and more. The small-character inkjet printers excel in producing alphanumeric characters, barcodes, logos, expiration dates, and batch numbers, ensuring crucial information is accurately marked onto products.

What sets CIJ printers apart is their ability to maintain exceptional print quality even on challenging surfaces and in dynamic production environments. Their non-contact printing process eliminates the risk of damaging delicate products, making them a reliable choice for industries with stringent quality standards.

One of the key advantages of CIJ printers is their flexibility in accommodating various inks, colors, and fonts. This adaptability allows businesses to comply with industry-specific regulations and create visually appealing codes that enhance brand identity. Additionally, CIJ printers offer real-time adjustments, enabling seamless coding changes and reducing downtime during production shifts.

As technology continues to advance, so do CIJ printers. Modern models are equipped with user-friendly interfaces, remote monitoring capabilities, and self-maintenance features, streamlining operations and minimizing the need for constant manual intervention.

In a rapidly evolving market, the importance of accurate and reliable product coding cannot be overstated. Small Character Inkjet Printers (CIJ) stand as the cornerstone of this critical process, embodying precision, versatility, and efficiency. Whether used for marking date codes on packaged foods or ensuring traceability in industrial components, CIJ printers empower businesses to meet the demands of modern coding requirements with finesse and confidence.

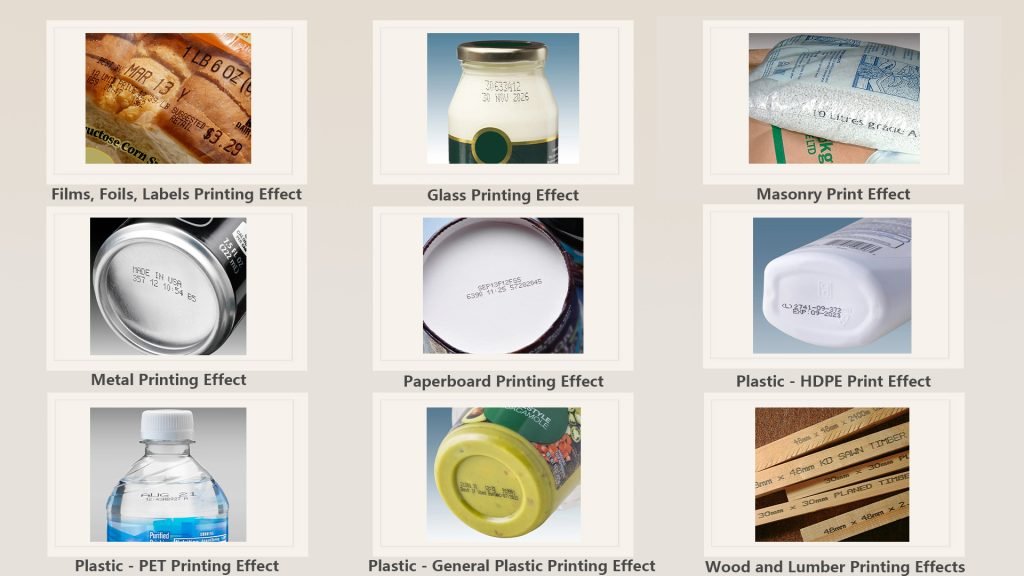

CIJ (Continuous Inkjet) printers are widely utilized across various industries for their versatile and reliable printing capabilities. They excel in marking products with clear and accurate codes on a wide range of substrates. Here are some industries where CIJ printers are commonly used and their printing effects:

CIJ printers are known for their excellent printing effects, characterized by high-speed printing, sharp and legible characters, and the ability to print on curved, uneven, or textured surfaces. They offer consistent print quality even in challenging environments, and their non-contact printing method minimizes the risk of damaging delicate products. Additionally, CIJ printers provide flexibility in terms of ink types, colors, and fonts, allowing businesses to create customized and visually appealing codes that align with their branding.

In summary, CIJ printers find extensive application across industries, offering reliable and efficient coding solutions that meet diverse marking needs while maintaining a high standard of print quality.

| Parameter | Specification |

|---|---|

| Print Technology | Continuous Inkjet (CIJ) |

| Nozzle Size | Typically 60 μm, 70 μm, or 75 μm (selectable) |

| Print Resolution | 60–120 dpi (depending on speed and drop size) |

| Line Speed Capability | Up to 300 m/min (varies by resolution and print content) |

| Character Height Range | 1 mm to 15 mm |

| Ink Types | MEK-based, ethanol-based, pigmented, UV-reactive, food-grade inks |

| Number of Print Lines | 1–5 lines (depending on font and speed) |

| Supported Content | Text, date/time, batch/lot codes, barcodes, serials, logos |

| Interface Options | USB, Ethernet, RS232, encoder, I/O ports |

| Controller | Industrial touchscreen or membrane panel |

| Ink System Features | Auto viscosity control, pressure regulation, solvent recovery |

| Operating Temperature | 5°C to 45°C (with heater options available) |

| IP Rating (Optional) | Up to IP65 for washdown or dusty environments |

CIJ printers have been a staple in industrial coding for decades, offering unmatched flexibility and high-speed marking capabilities. Here are some of their key advantages:

High-Speed Printing

CIJ printers are capable of printing clean, legible codes at speeds exceeding 300 meters per minute, making them ideal for bottling, extrusion, and cable industries.

Versatility Across Substrates

CIJ can print on almost any surface—from plastic, glass, and metal to flexible films and eggshells—using a wide variety of specialized inks.

Non-Contact Printing

The small ink drops can be projected over a gap, allowing printing on uneven, curved, or moving surfaces without requiring physical contact.

Dynamic Data Printing

Easily handles variable data such as real-time clocks, counters, barcodes, and custom messages, even on fast production lines.

Continuous Operation

Designed for 24/7 manufacturing environments, CIJ systems can run for extended periods with minimal user intervention.

Compact Printheads

Small and lightweight printheads are easy to integrate into tight spaces on high-speed lines.

At Cheef, we understand the importance of ensuring your investment arrives safely and in optimal condition. That’s why we take the utmost care in packaging our CIJ Inkjet Printers to provide you with peace of mind and a seamless experience from the moment you place your order to the moment your printer arrives at your doorstep.

Our packaging process goes beyond the standard to ensure that your CIJ Inkjet Printer is protected during transit. Each printer is meticulously packed with precision to prevent any potential damage that could occur during transportation. We use high-quality materials that cushion and shield your printer from impact, ensuring that it reaches you in the same impeccable condition as when it left our facility.

Our commitment to delivering excellence extends to every aspect of your experience with us. We know that a well-packaged product not only saves you from the frustration of receiving damaged goods but also reinforces the trust you place in us. When you unbox your CIJ Inkjet Printer, you can be confident that it’s ready to perform flawlessly, without any setbacks caused by shipping mishaps.

For your convenience and to showcase our dedication to the quality of our packaging, we have provided a video alongside this message. This video offers a firsthand look at how we expertly package our CIJ Inkjet Printers, ensuring they are well-protected and ready for safe transportation to your location.

At Cheef, we consider every detail to ensure that your experience with us is nothing short of exceptional. Our carefully crafted packaging not only reflects our commitment to quality but also serves as a testament to our dedication to your satisfaction.

Thank you for choosing Cheef. We look forward to providing you with a superior CIJ Inkjet Printer that arrives just as impressive as the technology it embodies.”

Q1: What makes CIJ printers different from other inkjet systems?

A: CIJ printers use a continuous stream of ink droplets, selectively deflected to form characters. Unlike DOD or TIJ, CIJ can print on non-porous, curved, or fast-moving surfaces at very high speeds.

Q2: What surfaces can CIJ printers code on?

A: CIJ is compatible with glass, metal, plastic, cable, eggshells, film, and more. Specialized inks allow coding in environments with condensation, oil, or heat exposure.

Q3: Are CIJ printers suitable for food or pharmaceutical products?

A: Yes. Many CIJ models support food-grade inks and are compliant with GMP or cleanroom environments. They’re used for expiry dates, lot numbers, and production info on medicine bottles and food packaging.

Q4: How much maintenance does a CIJ printer require?

A: CIJ systems require regular maintenance, including flushing printheads, cleaning filters, and managing ink viscosity. However, automated ink systems in modern CIJ printers reduce manual intervention.

Q5: Can CIJ printers print multiple lines of text?

A: Yes. Depending on the model and font, CIJ printers can print up to 5 lines of alphanumeric text or combinations of text and codes (e.g., time + batch + barcode).

Q6: What are the typical operating costs of a CIJ printer?

A: Operating costs include ink, solvent (make-up fluid), filters, and maintenance kits. While higher than TIJ or DOD in fluids, CIJ is still cost-effective for high-speed, high-volume operations.

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

A Thermal Transfer Overprinter (TTO) is an advanced digital printing device designed to deliver high-resolution, real-time variable data onto flexible packaging materials. Unlike traditional contact printing or hot stamp methods, TTO printers use a digitally controlled printhead and thermal transfer ribbon to produce clean, smudge-resistant codes such as expiration dates, batch numbers, barcodes, and logos — all with exceptional precision.

TTO technology is widely adopted in industries like food, pharmaceuticals, and cosmetics, where clarity, compliance, and speed are critical. It enables on-demand printing directly on film, labels, and foils with minimal waste and downtime.

By combining thermal precision with digital control, TTO printers represent the ideal solution for high-speed, high-volume production environments that demand efficiency without compromising print quality.

Watch how the 6230 and 6330 TTO printers bring efficiency and clarity to high-speed packaging lines. These models are engineered for reliability, delivering crisp, high-resolution codes on flexible packaging — all while minimizing downtime and ribbon waste.

Whether you’re printing date codes, barcodes, or batch information, this video demonstrates the seamless integration and powerful performance that make our TTO solutions the smart choice for modern production environments.

Thermal Transfer Overprinters (TTO) are trusted by manufacturers across a wide range of industries that require consistent, high-quality variable data printing on flexible packaging. Below are key sectors where TTO technology plays a vital role, along with real-world application examples:

In high-speed snack, bakery, and frozen food lines, TTO printers are used to print expiry dates, batch codes, and ingredient details directly onto flow-wrapped film or foil packs. For example, a cookie manufacturer may use a 6230 TTO printer to apply clear lot numbers and best-before dates on each wrapper, even at speeds exceeding 300 packs per minute.

Precision and compliance are non-negotiable. TTO printers help pharmaceutical companies print dosage instructions, serial numbers, barcodes, and traceability codes onto blister packs and sachets. A common use case includes printing unique 2D codes on medication sachets to support serialization requirements under global track-and-trace regulations.

Flexible sachets for shampoo, lotion, or beauty creams often require branding, manufacturing dates, and promotional messages to be printed directly on the packaging. TTO printers offer the sharp detail and smudge-free quality required for visually appealing personal care products.

TTO systems are ideal for printing “use-by” dates and packaging codes on yogurt lids, cheese wrappers, and milk pouch films, where condensation or low temperatures may challenge ink-based systems. The 6330, with its advanced ribbon-saving mode, is a preferred choice for such short-run applications.

Flexible pouches for pet treats or supplements require robust coding solutions. TTO technology ensures barcode accuracy and legibility on glossy laminated films — often essential for scanning and inventory management in retail environments.

Cleaning wipes, detergent pods, and refill pouches often use flexible packaging. TTO printers ensure durable and chemical-resistant markings even on slick surfaces.

TTO excels in printing high-resolution variable data on flexible packaging materials, such as snack wrappers, pouches, and sachets.

Best suited for flow-wrap lines, form-fill-seal machines, and film-based production requiring clean, smudge-proof date codes, barcodes, or logos.

Thermal Transfer Overprinters (TTO) are engineered to meet the demands of modern manufacturing — where precision, efficiency, and flexibility are non-negotiable. Here’s what sets TTO apart:

High-Resolution Printing

TTO systems deliver sharp, legible text and graphics up to 300 dpi, ensuring barcodes scan correctly and date codes remain readable even on high-gloss or textured films.

Zero Ink Mess

Unlike traditional ink-based systems, TTO printers use clean, dry ribbons. No fluid handling, no nozzle cleaning — just consistent print quality.

Ribbon Efficiency Technology

Smart ribbon-saving modes reduce waste by up to 60%, lowering operational costs without sacrificing print clarity.

Real-Time Data Integration

TTO printers can receive dynamic data from MES, ERP, or weighing systems — allowing automatic updates of lot numbers, variable weights, or promotional info on each pack.

Fast Changeovers

Digital template storage and tool-less ribbon loading simplify product switches, making TTO ideal for lines with frequent changeovers.

Understanding the differences between TTO, Continuous Inkjet (CIJ), and Hot Stamping is key to choosing the right solution for your production needs:

| Technology | Print Quality | Media | Consumables | Flexibility | Maintenance | Line Speed |

| TTO (Thermal Transfer Overprinting) | High resolution (up to 300 dpi); ideal for barcodes & logos | Flexible films, foils, labels | Ribbon (dry, clean) | Fully digital, prints variable data | Low – no nozzles, no ink build-up | High – perfect for flow-wrap and VFFS lines |

| CIJ (Continuous Inkjet) | Moderate resolution; suitable for fast-moving objects | Bottles, cans, rigid containers | Ink + solvent (liquid, requires maintenance) | Excellent for variable codes; not ideal for flexible films | Requires frequent cleaning and fluid monitoring | Very high – best for high-speed bottling |

| Hot Stamping | Fixed font, low clarity; poor for detailed or variable text | Foils, labels, cartons | Foil tape + dies (manual setup) | Static text only; one die per product | Mechanical wear over time | Slower – often used for low-speed packaging |

If your production involves flexible packaging, frequent SKU changes, and requires on-the-fly data updates, TTO printers are a future-proof choice. They combine the clarity of a label printer, the speed of an inkjet, and the versatility of a digital press — all in one compact solution.

| Parameter | Description |

|---|---|

| Print Technology | Thermal Transfer Overprinting (TTO) |

| Print Resolution | Up to 300 dpi |

| Max Print Area | Up to 53mm x 75mm (varies by model and configuration) |

| Print Speed | Up to 600mm/s (depending on substrate and layout) |

| Interface Options | USB, Ethernet, RS232, I/O |

| Touchscreen | 5” or 10” color touchscreen (model dependent) |

| Ribbon Width | 33mm / 55mm (selectable based on model) |

| Ribbon Length | Up to 1,200 meters |

| Print Modes | Intermittent & Continuous |

| Controller Features | Intuitive GUI, real-time preview, diagnostics tools |

| Power Requirements | 100–240V AC, 50/60Hz |

| Environmental Tolerance | 5°C – 40°C, non-condensing humidity |

| Mounting Compatibility | Easily integrated with VFFS, HFFS, and labelers |

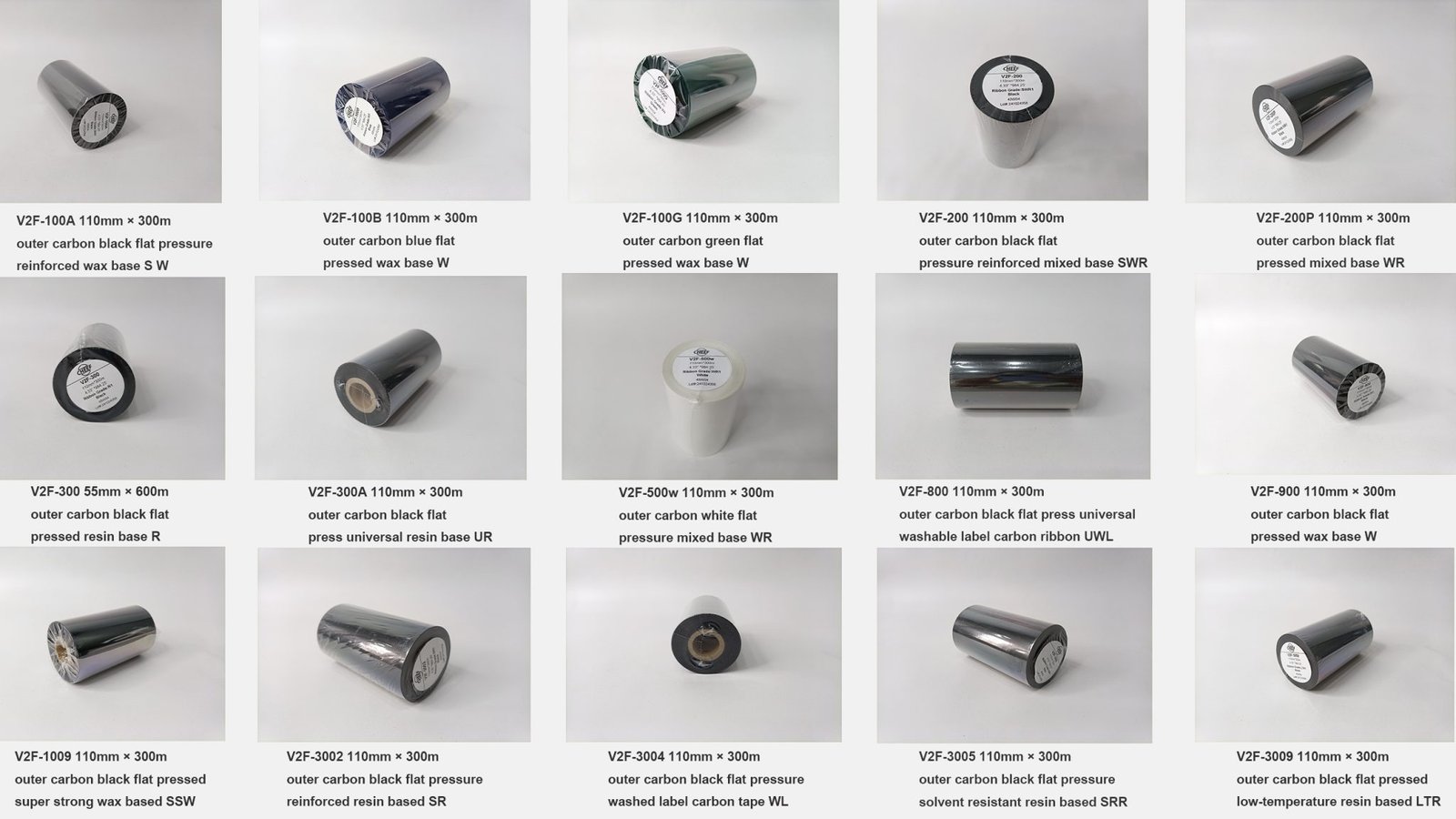

To ensure optimal performance and long-term reliability, we recommend using certified thermal transfer ribbons tested for compatibility with our TTO printers. Key options include:

Standard Wax-Resin Ribbons

Ideal for general-purpose flexible film coding with good scratch resistance and sharpness.

Premium Resin Ribbons

Suitable for demanding applications such as chemical packaging, freezer-grade film, and high-abrasion conditions.

FDA-Approved Food-Grade Ribbons

Safe for indirect food contact and compliant with industry regulations.

Ribbon Widths Available: 33mm / 55mm

Ribbon Colors Available: Black (standard), White, Red, Blue (optional on request)

Core Sizes: 1-inch plastic core, industry standard

🔧 For best results, always pair ribbons with recommended printhead pressure and heat settings according to material type.

Q1: What materials can be printed with TTO printers?

A: TTO printers are ideal for printing on flexible films, laminated foils, labels, and soft packaging materials used in food, pharmaceutical, and cosmetic industries.

Q2: How does TTO compare to inkjet printing?

A: TTO offers higher print resolution, cleaner operation (no ink spills), and better suitability for flexible packaging. However, inkjet is often preferred for rigid products like bottles or cans.

Q3: Can I switch between intermittent and continuous mode?

A: Yes, many models like the 6230 and 6330 support both modes. Switching is simple and depends on your packaging line configuration.

Q4: How often does the ribbon need to be replaced?

A: That depends on print density and ribbon length. With a 1200-meter roll and efficient ribbon-saving mode, ribbon changes can be minimized even in high-volume production.

Q5: What maintenance is required?

A: TTO systems require minimal maintenance — routine cleaning of the printhead and rollers is recommended. No ink handling or purging is needed.

Q6: Is integration with other systems like ERP or barcode scanners possible?

A: Absolutely. TTO printers can be integrated with MES, ERP, barcode scanners, and checkweighers for automated variable data printing.

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

A Thermal Inkjet Printer (TIJ) is a compact, high-resolution coding device that propels ink droplets onto surfaces using rapid thermal pulses. Unlike continuous inkjet (CIJ) systems, TIJ printers rely on heat to instantly vaporize a small portion of ink, creating micro-bubbles that push ink through nozzles without the need for moving parts or compressed air.

TIJ technology is especially valued for its clean operation, maintenance-free design, and crisp print quality, making it ideal for applications requiring precise alphanumeric codes, barcodes, and QR codes on porous and semi-porous substrates.

Modern TIJ systems are often modular, cartridge-based, and ready for integration with packaging lines across industries such as food and beverage, electronics, pharmaceuticals, and logistics. With fast startup times and simple interface controls, TIJ printers are a smart choice for companies seeking flexibility, minimal downtime, and low operational cost.

The TIJ 8520 thermal inkjet printer deliver sharp, high-contrast codes on various packaging materials with speed and precision. It prints barcodes, expiration dates, and lot numbers — all without maintenance or warm-up delays.

Whether you’re coding on cartons, labels, or secondary packaging, the 8520 proves why it’s a preferred solution for industries that demand reliability, clarity, and ease of use.

Thermal Inkjet (TIJ) printers are trusted across a diverse range of industries that demand clean, high-resolution, and low-maintenance coding. Their compact form and cartridge-based design make them ideal for integration into existing production lines. Below are key sectors benefiting from TIJ technology:

TIJ printers are used to print expiry dates, batch codes, and QR codes on cartons, labels, and bottle caps. Their fast-drying inks support high-speed operations without smudging, even in humid environments.

In this heavily regulated sector, TIJ systems provide sharp 2D codes, serial numbers, and tamper-evident markings for traceability and compliance with GS1 and FDA requirements.

TIJ enables high-resolution coding of model numbers, part codes, and barcodes directly onto cardboard packaging, pouches, or coated cartons, maintaining legibility even in fine print.

In shipping and fulfillment centers, TIJ printers are ideal for applying shipping codes, date stamps, and tracking information onto corrugated boxes, tapes, or labels on the fly.

Brands rely on TIJ to add batch IDs and promotional data to outer cartons and flexible pouches without affecting packaging aesthetics.

TIJ printers are widely used to mark lot numbers, production dates, and supplier codes on packaging for components such as filters, bearings, and electrical modules. Their ability to print clearly on corrugated cartons and coated boxes makes them a practical solution in supply chain environments where traceability is critical.

TIJ printers combine precision engineering with operational simplicity, making them a compelling solution for a wide variety of printing tasks:

High-Resolution Output (Up to 600 dpi)

Delivers razor-sharp codes, logos, and barcodes suitable for both consumer-facing and regulatory applications.

Cartridge-Based System

No ink bottles, no spills. Ink and printhead are combined, so every new cartridge gives a clean start with no servicing required.

Maintenance-Free Operation

No moving parts, no downtime — just plug in the cartridge and print. Perfect for decentralized or remote production.

Quick Integration

Compact size, modular mounting options, and fast installation make TIJ printers an easy fit for almost any packaging line.

Multi-Cartridge Flexibility

Supports a wide range of ink types (solvent-based, water-based, UV-curable) for porous and non-porous surfaces.

Cost Efficiency

Pay only for what you use. No periodic maintenance, no make-up fluid, and minimal training required.

| Feature | TIJ (Thermal Inkjet) | CIJ (Continuous Inkjet) |

|---|---|---|

| Print Resolution | High (up to 600 dpi) – excellent for barcodes/text | Moderate (60–120 dpi) – suitable for basic coding |

| Maintenance | Zero – cartridge-based with no servicing needed | High – requires flushing, filters, and skilled service |

| Startup Time | Instant – no warm-up needed | Several minutes – depending on fluid system readiness |

| Ink Delivery System | Sealed cartridges – clean and mess-free | Open fluid tanks – potential for leaks or fumes |

| Best for | Short to medium runs, clean environments | High-speed, high-volume production |

| Substrate Compatibility | Paper, cardboard, blister film, coated labels | Bottles, cans, flexible film, metal |

| Typical Applications | Expiry dates, barcodes, lot codes on cartons | Batch codes on beverage bottles, extrusions, cables |

| Line Speed Capability | Up to 90 m/min (depending on dpi and layout) | 200+ m/min for fast-moving production lines |

| Parameter | Specification |

|---|---|

| Print Technology | Thermal Inkjet (TIJ) using cartridge-based ink delivery |

| Maximum Print Resolution | Up to 600 dpi (dots per inch) |

| Maximum Print Height | 12.7 mm per cartridge (expandable with multi-head setup) |

| Printing Speed | Up to 76 m/min at 300 dpi / Up to 30 m/min at 600 dpi |

| Ink Types Supported | Water-based, solvent-based, and specialty inks (UV, MEK, ethanol) |

| Substrate Compatibility | Paper, cardboard, coated cartons, films, plastics, blister foils |

| Interface Options | USB, RS232, Ethernet, encoder and I/O ports |

| Touchscreen Display | 7” full-color LCD touchscreen with user-friendly GUI |

| Message Storage | Up to 999 messages, easily switchable |

| Power Supply | 100–240V AC, 50–60 Hz |

| Operating Temperature | 5°C to 40°C |

| Mounting Options | Bracket-ready for conveyor, labelers, flow-wrappers |

| Software Compatibility | Windows-based software for layout design and data import (optional) |

Q1: What surfaces can TIJ printers print on?

A: TIJ printers are suitable for porous and semi-porous materials like paperboard, cartons, kraft boxes, and some coated films. With solvent inks, they can also print on plastics and foils.

Q2: Is TIJ suitable for high-speed production lines?

A: Yes, TIJ systems can print at speeds up to 76 m/min depending on resolution. For extremely high-speed bottling or cable lines, CIJ may be preferred.

Q3: How is maintenance handled for TIJ printers?

A: TIJ printers are virtually maintenance-free. Each new ink cartridge includes a fresh printhead, eliminating the need for cleaning or calibration.

Q4: How often do I need to replace cartridges?

A: Cartridge life depends on message size, resolution, and coverage. On average, a standard 42 ml cartridge yields 300,000–500,000 prints at 300 dpi with 6–8 characters.

Q5: Can TIJ printers print variable data like barcodes or time stamps?

A: Absolutely. TIJ printers support real-time data including timestamps, expiration dates, lot numbers, serial numbers, barcodes, and QR codes.

Q6: Is integration with my packaging line or ERP system possible?

A: Yes. Most TIJ printers offer encoder, sensor, and Ethernet ports, making them easily connectable with PLCs, checkweighers, scanners, or database systems.

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

A Drop-on-Demand (DOD) Large Character Printer is an industrial inkjet coding system designed to produce bold, high-visibility prints—typically on porous or secondary packaging materials such as corrugated boxes, wood pallets, or sacks. Unlike continuous inkjet systems, DOD printers only fire ink droplets when required, offering efficient ink usage and simplified maintenance.

DOD technology is ideal for applications that demand large alphanumeric characters, logos, or barcodes, with character heights typically ranging from 12 mm up to over 320 mm, depending on the printhead configuration. The print process uses either valve jet or piezo technology to eject ink droplets in a controlled pattern directly onto the substrate.

Known for their durability, low operating costs, and robust design, DOD printers are often deployed in harsh industrial environments—such as building materials, chemical packaging, cement bags, and shipping lines—where clarity, permanence, and ruggedness matter most.

With the ability to operate reliably in dusty, humid, or high-vibration settings, DOD systems are an excellent solution for manufacturers seeking large, readable codes with minimal maintenance and high uptime.

Drop-on-Demand (DOD) large character printers are purpose-built for heavy-duty, high-contrast printing needs. They are ideal for industries that require bold, permanent, and highly readable prints on rough or porous surfaces, where small characters would be impractical or invisible.

DOD printers are widely used for printing brand names, product specifications, and lot numbers on materials such as concrete blocks, gypsum boards, roofing tiles, insulation sheets, and timber. The robust printheads withstand dusty, high-vibration conditions.

For multi-wall paper sacks and woven bags, DOD printers deliver large and durable codes directly on bag surfaces. Printing remains legible even through handling, stacking, and shipping.

In logistics and secondary packaging, DOD systems apply case numbers, barcodes, and shipping details to outer cartons, wooden crates, or shrink-wrapped pallets. Their large-format print ensures visibility from a distance.

DOD technology is suited for marking batch info and traceability codes on bags of granular fertilizers, animal feed, or grain sacks — especially in outdoor production or filling environments.

In the steel and pipe industries, DOD printers mark identification numbers and size codes on metal tubes, sheets, and bundles using high-adhesion inks that can resist heat, moisture, and abrasion.

In beverage and bulk liquid industries, DOD printers are used to mark production dates, product codes, and traceability information on large containers such as drums, barrels, and shrink-wrapped trays. The high ink throw distance and bold character size make them ideal for uneven or curved surfaces like plastic kegs or corrugated trays — even under wet or humid conditions common in bottling plants.

| Parameter | Specification |

|---|---|

| Print Technology | Drop-on-Demand (Valve Jet or Piezoelectric) |

| Character Height | Typically 12 mm to 120 mm (per head); customizable with multi-head setup |

| Print Resolution | Up to 180 dpi (variable based on model and head spacing) |

| Printing Speed | Up to 90 m/min (application dependent) |

| Ink Compatibility | Water-based, MEK, oil-based, or pigmented inks |

| Substrate Compatibility | Porous and semi-porous materials (corrugated boxes, wood, sacks, concrete) |

| Control Interface | Touchscreen controller or remote PC-based software |

| Connectivity | Ethernet, RS232, Encoder, External Sensor, PLC I/O |

| Head Configuration | Single to multi-head (up to 4 heads per system) |

| Operating Conditions | 0°C to 50°C, high dust/humidity resistance models available |

| Mounting Options | Bracket or custom integration for conveyor and pallet lines |

| Feature / System | DOD (Drop-on-Demand) | CIJ (Continuous Inkjet) | TIJ (Thermal Inkjet) |

|---|---|---|---|

| Target Use | Large, bold codes on outer packaging | Small to medium codes on fast-moving items | High-res printing on boxes, labels, cartons |

| Character Size Range | 12 mm to 120+ mm | 1 mm to 15 mm | 1 mm to 12.7 mm per cartridge |

| Print Resolution | Medium (up to 180 dpi) | Low–Medium (60–120 dpi) | High (up to 600 dpi) |

| Best Substrates | Corrugated, wood, concrete, sacks | Bottles, pouches, cables | Cartons, labels, coated paper |

| Maintenance | Low – rugged valve/piezo heads | High – regular flushing and filter replacement | Virtually none – cartridge-based system |

| Ink Type | High-viscosity, oil or water-based inks | Solvent-based inks | Cartridge-based solvent or aqueous inks |

| Print Speed | Moderate (up to 90 m/min) | Very high (200+ m/min) | Moderate (30–76 m/min depending on dpi) |

| Cost of Ownership | Low – economical in high-volume industrial use | Moderate to high due to fluids and service | Low – pay-per-cartridge with zero maintenance |

| Common Industries | Construction, chemicals, logistics, heavy goods | Beverage, cable, FMCG | Food, pharma, logistics, retail |

Q1: What is a DOD printer best used for?

A: DOD printers are ideal for printing large, bold text, numbers, barcodes, or logos onto secondary packaging such as cartons, sacks, wooden crates, and pallets. Their rugged design makes them especially suitable for harsh industrial environments.

Q2: What’s the difference between DOD and CIJ printing?

A: CIJ systems are used for small characters on fast-moving products like bottles or cables, while DOD printers specialize in large-character codes on porous materials or outer packaging. DOD systems are generally lower maintenance and more robust.

Q3: Can DOD printers print barcodes or graphics?

A: Yes. Modern DOD systems can print 1D barcodes, simple 2D codes, company logos, and other fixed-format graphics. While resolution is lower than thermal inkjet, DOD codes are designed for long-distance readability and durability.

Q4: What kind of inks do DOD printers use?

A: DOD printers support high-viscosity inks including water-based, oil-based, solvent-based, and pigmented inks. Ink selection depends on the surface (e.g., wood, concrete, carton) and required durability (e.g., UV or abrasion resistance).

Q5: Are DOD printers maintenance-intensive?

A: Not at all. Compared to CIJ systems, DOD printers are low-maintenance. Valve-based or piezo printheads are built to endure industrial conditions, and ink systems typically require minimal intervention.

Q6: How many printheads can a DOD system support?

A: Depending on the model, one DOD controller can drive one to four printheads, enabling multi-line or multi-location printing on large packages or pallets. Each head can be configured independently for size and layout.

Q7: Can DOD printers operate in dusty or humid environments?

A: Yes. DOD systems are commonly installed in cement plants, sawmills, and warehouses, where dust, moisture, or temperature changes are common. Models with IP-rated enclosures are available for more demanding environments.

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

A High-Resolution Inkjet Printer (HRIJ) is an industrial printing system engineered to deliver exceptionally sharp, detailed prints on porous and semi-porous substrates. Utilizing piezoelectric or thermal inkjet technology, HRIJ systems are capable of printing complex elements such as barcodes, logos, serialized data, and small fonts with resolutions typically ranging from 180 dpi to over 600 dpi.

Unlike low-resolution printers designed for basic text marking, high-resolution models are intended for applications where code clarity, scanability, and branding visibility are critical. The ink delivery system, often powered by high-density nozzles and intelligent control algorithms, enables precise droplet placement for consistent, clean results — even at varying speeds.

HRIJ printers are widely used for secondary packaging, product branding, inventory management, and retail compliance, particularly in industries such as food, beverage, pharmaceuticals, and e-commerce logistics. Their modular design, maintenance efficiency, and ability to integrate with production lines make them a popular alternative to traditional labeling or pre-printed cartons.

High-Resolution Inkjet Printers (HRIJ) are ideal for applications requiring precise, sharp, and scan-grade printing directly onto packaging materials. These printers are particularly well-suited for carton-level traceability, retail compliance, and graphic branding.

Used for printing GS1 barcodes, batch information, expiry dates, and logos on outer cartons, shrink-wrapped trays, and paperboard packaging. HRIJ systems ensure traceability and clear product identification.

In pharmaceutical distribution, HRIJ printers deliver high-resolution serialized codes and 2D barcodes (e.g., DataMatrix) required for global track-and-trace regulations.

HRIJ technology is widely used for inventory codes, QR codes, and shipping details on corrugated boxes. The high DPI output ensures barcodes scan reliably throughout the supply chain.

As demand for branded and coded secondary packaging grows, HRIJ printers provide on-demand printing of variable data such as customer orders, SKU numbers, or return barcodes directly on mailer boxes.

Used for lot numbers, promotional graphics, and brand logos on coated cartons and labels, helping avoid the need for costly pre-printed packaging.

HRIJ systems apply model codes, serials, and compliance marks (e.g., CE, RoHS) on packaging for power tools, home appliances, or electronic accessories.

| Parameter | Specification |

|---|---|

| Print Technology | High-Resolution Inkjet (Piezo or Thermal inkjet-based) |

| Resolution | Up to 600 dpi (horizontal and vertical) |

| Print Height | 12.7 mm per printhead; scalable with stacked/multiple heads |

| Print Speed | Up to 60 m/min at 300 dpi; variable with resolution settings |

| Supported Content | Barcodes (1D/2D), logos, text, expiration dates, counter, variable data |

| Ink Types | Oil-based, UV-curable, solvent-based inks (pigmented or dye-based) |

| Substrate Compatibility | Corrugated boxes, coated cartons, paperboard, labels, shrink wraps |

| Data Interface | USB, Ethernet, PLC I/O, Encoder, External Sensor |

| Controller | Touchscreen panel or external PC with label design software |

| Mounting Options | Adjustable brackets for conveyors, case erectors, tapers, or labelers |

| Maintenance | Low – automatic purging and self-cleaning features in most models |

Exceptional Print Clarity

With resolutions up to 600 dpi, HRIJ systems deliver crystal-clear barcodes, logos, and small-sized text ideal for regulatory or customer-facing content.

Label Replacement Capability

Directly print variable data on cartons or cases, reducing dependency on pre-printed labels and lowering consumable costs.

Fast & Flexible Integration

Easily integrates with existing production lines via modular mounting kits, with encoder/sensor support for real-time speed control.

Wide Ink Compatibility

Works with oil-based inks for porous substrates and solvent or UV-based inks for coated or semi-porous surfaces.

Low Maintenance Design

Many models feature auto-cleaning nozzles, bulk ink systems, and remote diagnostics for minimal downtime.

Eco-Friendly Coding

Reduces label waste and adhesive contamination by printing directly on packaging materials.

| Feature | HRIJ (High-Res Inkjet) | TIJ (Thermal Inkjet) | CIJ (Continuous Inkjet) |

|---|---|---|---|

| Resolution | Up to 600 dpi | Up to 600 dpi | 60–120 dpi |

| Best For | Barcodes, logos, carton-level branding | Box coding, lot numbers, small format coding | Date/batch coding on bottles, films, cables |

| Substrates | Corrugated boxes, cartons, paperboard | Cartons, labels, pouches | Plastics, metals, glass, flexible film |

| Ink Delivery | Bulk or cartridge systems (external tanks) | Sealed cartridges | Ink + solvent via recirculating system |

| Print Height | Up to 50+ mm (multi-head) | Up to 12.7 mm | Up to 15 mm |

| Maintenance | Low – auto cleaning systems | Zero – replaceable cartridge | High – regular cleaning and servicing required |

| Barcoding Capability | Full 1D/2D barcode support (GS1, QR, DataMatrix) | Basic barcodes, some 2D with modules | Basic alphanumeric codes, limited barcode support |

| Cost Efficiency | Medium – optimized for case-level printing | Low – great for short runs | Moderate – optimized for continuous speed coding |

Q1: What makes a printer “high-resolution”?

A: A high-resolution inkjet printer typically offers print resolutions of 180 to 600 dpi or higher, allowing it to produce sharp barcodes, logos, and small text with excellent edge definition. This distinguishes it from lower-resolution CIJ or DOD systems used mainly for simple codes.

Q2: What packaging materials are compatible with HRIJ printers?

A: HRIJ printers are compatible with corrugated cardboard, coated cartons, kraft paper, paperboard, shrink wrap, and labels. Using the right ink type (oil-based, solvent-based, or UV), they can also print on semi-porous and lightly coated surfaces.

Q3: Can high-resolution printers replace label printers?

A: Yes. HRIJ systems are often used to replace thermal transfer or label applicators, allowing direct printing of variable data like barcodes, logos, and expiry dates on boxes — reducing label waste and consumable costs.

Q4: What types of barcodes can be printed?

A: HRIJ printers support a wide range of barcode formats including Code 128, Code 39, ITF, EAN, QR codes, and GS1 DataMatrix, with print quality suitable for scanning at retail and distribution centers.

Q5: Are HRIJ printers easy to integrate into production lines?

A: Absolutely. Most high-resolution printers offer modular printheads, adjustable mounting brackets, encoder and sensor support, and industrial communication protocols like Ethernet and RS232 for seamless integration.

Q6: How is maintenance handled?

A: HRIJ systems are designed for low maintenance. Many models come with auto-purge, nozzle cleaning, and bulk ink management features. Daily cleaning is rarely needed unless using fast-drying solvent or UV inks.

Q7: Can I use one printer for multiple carton sizes?

A: Yes. The print layout can be customized for different message heights, widths, and positions. With multiple printheads or adjustable mounting, one HRIJ printer can handle a wide range of carton sizes on the same line.

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

An LPA (Label Print and Apply) machine is an automated system designed to print variable information on labels and apply them directly to products or packaging in real time. Unlike pre-printed label applicators, LPA systems combine an industrial-grade label printer with a precision applicator, enabling on-demand printing of barcodes, text, logos, and serialized data.

LPA machines are commonly integrated into production lines to label cartons, cases, pallets, and individual products, ensuring accurate placement, consistency, and compliance with traceability and retail standards. These machines support thermal transfer or direct thermal printing technologies, depending on durability requirements.

Equipped with features like corner wrap, top/bottom apply, tamp-blow, or wipe-on application methods, LPA systems are versatile and customizable for a wide range of packaging shapes and production speeds. They are widely used in industries such as food and beverage, pharmaceuticals, logistics, personal care, and e-commerce.

By automating the label printing and application process, LPA systems reduce manual labor, improve labeling accuracy, and ensure real-time data integration from ERP, WMS, or MES systems.

LPA (Label Print & Apply) systems are used across industries that demand on-the-fly printing of variable data and precise label application on packaging. Their strength lies in combining real-time label generation with automatic placement, enabling traceability, compliance, and efficiency.

Used for printing and applying nutrition labels, expiry dates, batch numbers, and barcodes on cartons, shrink-wrapped trays, and pallets — even at high speeds in cold or humid environments.

LPA machines ensure precise, regulation-compliant labeling for secondary packaging and outer cases, including serialized codes and tamper-evident tracking information.

Essential for real-time shipping label application, including SSCC, GTIN, and 2D barcodes, directly from warehouse management systems (WMS) to cartons and pallets for outbound tracking.

Apply order-specific labels, return labels, and tracking IDs automatically on shipping boxes at high throughput — reducing human error and manual handling.

LPA systems help brands automate price labels, SKU tags, branding stickers, or promotional labels across different product configurations with high precision.

Ensure safe and compliant labeling on hazardous material containers, drums, or bulk cartons, often including GHS-compliant pictograms and multi-language content.

| Parameter | Specification |

|---|---|

| Print Technology | Thermal Transfer or Direct Thermal |

| Print Resolution | 200 dpi / 300 dpi (optional) |

| Label Width | 25 mm – 110 mm (standard), up to 170 mm (wide models) |

| Label Length | 15 mm – 300 mm |

| Print Speed | Up to 300 mm/sec (depending on resolution) |

| Application Methods | Tamp, Blow-on, Tamp-Blow, Wipe-On, Corner Wrap, Top/Side/Bottom Apply |

| Max Throughput | Up to 40 labels/min (depends on label size and apply method) |

| Data Connectivity | Ethernet, USB, RS232, I/O, PLC, ERP/WMS integration |

| Label Roll Diameter | Max 300 mm (12”) |

| Environmental Conditions | 5°C – 45°C; optional enclosures for washdown or dust-prone areas |

| Mounting | Conveyor frame mounting or customized floor stand |

Real-Time Variable Data Printing

Instantly prints and applies labels with up-to-date barcodes, product details, or tracking codes, removing the need for pre-printed label stock.

Multi-Surface Labeling

Supports labeling on flat, curved, recessed, or cornered surfaces using flexible applicator arms and sensors.

Consistent Placement Accuracy

Mechanical precision ensures labels are applied consistently and squarely, reducing mislabeling risk.

Automated Workflow Integration

Fully integrates with ERP, WMS, MES, barcode scanners, and checkweighers for a seamless labeling process.

High Throughput Capability

Designed to run 24/7 with minimal operator intervention, making them ideal for high-volume lines.

Label-on-Demand Efficiency

Reduces waste and inventory of pre-printed labels by generating labels as needed, per order or SKU.

| Feature / Method | LPA (Label Print & Apply) | Pre-Printed Labels | Direct Coding (TIJ/CIJ) |

|---|---|---|---|

| Variable Data Printing | Yes – Real-time printing | No – Fixed content only | Yes – Real-time printing |

| Print Quality | High – Thermal Transfer (200–300 dpi) | High (offset/flexo pre-printing) | Medium–High (TIJ: 300–600 dpi, CIJ: 60–120 dpi) |

| Labeling Flexibility | High – Applies to many surfaces | Medium – Requires correct label format | Low – Limited to compatible surfaces |

| Changeover Time | Minimal – Digital templates | Medium – Requires changing rolls | Instant – Message change on screen |

| Integration with ERP/WMS | Full integration possible | Not applicable | Available on smart models |

| Maintenance | Low to moderate | None (applied manually or by simple machine) | TIJ: low, CIJ: high |

| Best For | Cartons, pallets, shipping boxes | Brand labels, cosmetics, specialty print effects | Expiry codes, batch numbers, bottle coding |

Q1: What’s the difference between LPA and a traditional label applicator?

A: Traditional label applicators apply pre-printed labels, while LPA systems print variable data on-demand and apply the label in one automated step. LPA is ideal for real-time information like dates, barcodes, and serialized IDs.

Q2: What printing technology is used in an LPA system?

A: LPA systems typically use thermal transfer (for durable prints) or direct thermal (for temporary or short-shelf-life items), depending on the application and material.

Q3: What types of surfaces can an LPA machine apply labels to?

A: LPA systems can label flat, curved, recessed, or even corner-wrapped surfaces. Applicator types such as tamp, blow-on, wipe-on, and corner-wrap can be configured to suit different product geometries.

Q4: Can I print barcodes and QR codes with an LPA machine?

A: Absolutely. LPA printers support 1D barcodes (e.g., Code 128, EAN), 2D codes (e.g., QR, DataMatrix), text, logos, and other variable content with high print resolution (200–300 dpi).

Q5: Is it possible to integrate the LPA system with my ERP or WMS?

A: Yes. Most LPA systems support integration with ERP, MES, WMS, or PLC systems via Ethernet, serial ports, or custom APIs, allowing real-time label generation based on production or order data.

Q6: What label sizes are supported?

A: Typical LPA systems support label widths from 25 mm to 110 mm, and lengths from 15 mm to 300 mm. Wider formats (up to 170 mm) are available in specialized models.

Q7: How fast can an LPA system apply labels?

A: Labeling speed depends on the label size and application method. For example, tamp-blow can apply up to 30–40 labels per minute, while wipe-on methods may support faster throughput.

Q8: How is maintenance handled?

A: Maintenance is generally low. Common tasks include replacing ribbon and label rolls, cleaning the printhead, and checking pneumatic components (if used). Many models offer remote diagnostics and error alerts.

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

A Laser Marking Machine is a high-precision, non-contact coding system that uses a focused laser beam to create permanent marks on the surface of materials. Unlike traditional printing methods that rely on ink, ribbons, or labels, laser marking modifies the material itself — through processes like etching, ablation, annealing, foaming, or color change — to produce highly durable and legible information.

Laser marking is ideal for encoding serial numbers, barcodes, logos, expiration dates, and traceability data on a wide variety of substrates, including metals, plastics, glass, paperboard, and ceramics. Depending on the application, the system may use fiber lasers, CO₂ lasers, or UV lasers, each suited for different material types and marking effects.

Laser systems offer exceptional accuracy, zero consumables, minimal maintenance, and high-speed performance. These features make them a preferred solution for industries such as pharmaceuticals, automotive, electronics, packaging, aerospace, and food production — where permanent identification, regulatory compliance, and marking quality are critical.

In modern production lines, laser marking machines can be easily integrated with conveyors, robotic arms, or vision systems, and configured for both static and dynamic (on-the-fly) marking operations.

Laser marking systems are widely used in sectors that require permanent, high-contrast, and maintenance-free identification on products and packaging. Their ability to mark without ink or labels makes them ideal for clean, fast-paced, and regulation-sensitive environments.

Laser machines mark lot numbers, 2D DataMatrix codes, and expiry dates on blister packs, glass vials, syringes, and stainless steel surgical tools — all while meeting UDI and traceability regulations.

Used for permanent marking of VIN codes, serial numbers, QR codes, and logos on engine parts, dashboards, wiring, and aluminum components, providing resistance to heat, oil, and wear.

High-precision lasers are used to engrave model numbers, polarity marks, micro-QR codes, and branding on PCBs, chip surfaces, plastic housings, and connectors, even at miniature sizes.

CO₂ lasers are often used to mark expiry dates and batch codes directly onto PET bottles, laminated cartons, caps, and flexible film — with no risk of ink migration or contamination.

Laser marking ensures brand protection by applying anti-counterfeit marks, batch codes, and logos on tubes, jars, or packaging boxes, maintaining aesthetic appeal without labels.

Laser coders print meters, logos, and time stamps on moving cables, PVC pipes, and tubes without contact — ideal for high-speed production with zero smudging.

| Parameter | Specification |

|---|---|

| Laser Source Types | CO₂, Fiber, UV (based on material & application) |

| Marking Area | 100 x 100 mm to 300 x 300 mm (varies by lens) |

| Marking Speed | Up to 12,000 mm/s (depending on material & resolution) |

| Resolution | Up to 1000 dpi equivalent |

| Supported Materials | Plastics, glass, metals, wood, rubber, cardboard, ceramics |

| Marking Modes | Static (standalone) or Dynamic (on-the-fly with encoder) |

| Cooling | Air-cooled or water-cooled (model dependent) |

| Power Output | Fiber: 10W–50W; CO₂: 10W–60W; UV: 3W–10W |

| Interface Options | Ethernet, RS232, USB, I/O, Encoder, PLC connectivity |

| Software Features | Variable text, serial numbers, barcodes, logos, timestamps, database access |

| Environmental Conditions | 5°C – 45°C; IP54/IP65 options for dusty or humid environments |

Permanent, Tamper-Proof Marking

Ideal for compliance and traceability — marks do not fade, smudge, or wear off over time.

Zero Consumables

No need for ink, solvents, ribbons, or labels — reducing long-term operational costs.

High-Speed, High-Precision Coding

Capable of marking thousands of parts per hour with precise control over font, depth, and contrast.

Versatile Marking Capabilities

Supports text, serial numbers, barcodes, logos, 2D codes, UDI data, and more.

Environmentally Friendly

No emissions, no waste consumables, and minimal energy consumption during marking.

Low Maintenance Requirements

No moving parts in the laser head and no fluid systems, reducing mechanical failures and downtime.

Safe Integration

Laser coders can be enclosed with interlocks, fume extraction, and Class 1 laser safety housings for operator safety.

| Feature | CO₂ Laser | Fiber Laser | UV Laser |

|---|---|---|---|

| Best For | Organic materials (cardboard, PET) | Metals, plastics, anodized aluminum | Sensitive plastics, glass, flexible film |

| Wavelength | 10.6 μm | 1064 nm | 355 nm |

| Marking Method | Surface etching, foaming | Etching, engraving | Photochemical reaction (cold marking) |

| Materials Supported | Paper, wood, PET, rubber | Stainless steel, brass, ABS, aluminum | PVC, HDPE, glass, medical plastics |

| Speed | Fast | Very fast | Moderate (higher resolution) |

| Mark Contrast | Medium | High | Ultra-high (no thermal distortion) |

| Cost | Moderate | Moderate to high | High (but precise for sensitive use) |

| Typical Industries | Food, beverage, packaging | Automotive, tools, electronics | Pharma, cables, microelectronics |

Q1: What materials can laser marking machines handle?

A: Laser marking systems can mark a wide range of materials including metals, plastics, ceramics, glass, wood, rubber, and cardboard. The appropriate laser type (Fiber, CO₂, UV) is selected based on the substrate.

Q2: Is laser marking permanent?

A: Yes. Laser marking is one of the most durable and tamper-proof coding methods. The marks are resistant to abrasion, solvents, heat, and environmental conditions — ideal for regulatory compliance and long-term traceability.

Q3: Does laser marking damage the product surface?

A: No, when properly configured. Laser parameters such as power, frequency, and focus are fine-tuned to ensure the surface is marked without compromising the product’s structure or appearance — especially for sensitive materials like medical plastics or PCBs.

Q4: What maintenance is required for a laser marking system?

A: Laser systems are generally low-maintenance, with no inks or moving parts in the printhead. Routine maintenance may include lens cleaning, air filter replacement, and occasional optical alignment, depending on the environment.

Q5: Can I mark dynamic information like barcodes or batch codes on-the-fly?

A: Absolutely. Laser systems support real-time variable data printing including date/time stamps, serial numbers, GS1 barcodes, and QR codes. They can operate in on-the-fly mode using encoder and sensor input for products in motion.

Q6: How do laser systems ensure operator safety?

A: Industrial laser marking systems include Class 1 enclosures, interlocks, fume extraction, and shielding to ensure full compliance with international safety standards. Many models are designed for operator-free environments.

Q7: Is laser marking faster than inkjet or label systems?

A: Yes, in many cases. Laser systems can mark hundreds of items per minute depending on the complexity of the mark and material. They also eliminate stoppages due to ink refills or label jams.

Choosing the right laser marking system depends on the industry, material, and marking requirements. Here’s a practical guide:

| Industry | Recommended Laser Type | Reason |

|---|---|---|

| Food & Beverage Packaging | CO₂ Laser | Ideal for marking on PET bottles, paper labels, film, no consumables |

| Pharmaceutical & Medical | UV Laser | High-precision, cold marking on sensitive plastics and glass |

| Automotive Components | Fiber Laser | Deep engraving, permanent VIN codes and logos on metals |

| Electronics / PCBs | UV or Fiber | Precise marks on small parts, circuit boards, no material distortion |

| Cable & Pipe Extrusion | Fiber Laser | Non-contact, high-speed marking on moving plastic or metal products |

| Cosmetics / Consumer Goods | CO₂ or Fiber | Permanent yet aesthetic marks on packaging, containers, or tubes |

| Industrial Tools / Hardware | Fiber Laser | Durable serial numbers, lot codes, and brand info on steel, alloys |

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

This comprehensive guide compares seven major industrial coding technologies, helping manufacturers and integrators understand their differences, strengths, and best-fit applications across various industries.

TIJ – Thermal Inkjet

CIJ – Continuous Inkjet

DOD – Drop-on-Demand (Large Character)

HRIJ – High-Resolution Inkjet

TTO – Thermal Transfer Overprinter

LPA – Label Print & Apply

Laser – Laser Marking System

| Feature / Technology | TIJ | CIJ | DOD | HRIJ | TTO | LPA | Laser |

|---|---|---|---|---|---|---|---|

| Marking Method | Bubble ejection | Continuous ink stream | Valve/piezo ink drop on demand | High-res piezo inkjet | Thermal ribbon transferred via heat | On-demand label print + application | Laser beam etching/modification |

| Resolution | Up to 600 dpi | 60–120 dpi | 100–180 dpi | Up to 600 dpi | 300 dpi | 200–300 dpi (printer) | Equivalent to 1000+ dpi |

| Substrate Types | Cartons, labels | Bottles, films, cables | Corrugated boxes, sacks | Cartons, coated board, labels | Flexible films (BOPP, PET, PE) | Cartons, pallets, shrink wrap | Metals, plastics, glass, ceramics |

| Print Height | Up to 12.7 mm per cartridge | Up to 15 mm | 12–120+ mm | Up to 50+ mm | 32–53 mm typical | Label sizes: 25–170 mm width | Variable (lens controlled) |

| Line Speed Capability | Up to 76 m/min | 300+ m/min | Up to 90 m/min | Up to 60 m/min (at 300 dpi) | Up to 600 mm/s (intermittent/cont.) | Up to 40 labels/min | 1000+ parts/min |

| Consumables | Ink cartridges | Ink + solvent + filters | Bulk ink | Bulk or modular ink | Wax-resin or resin ribbon | Blank labels + ribbons | None |

| Maintenance Level | Very low | High | Low | Low | Low | Medium | Very low |

| Typical Use Case | Expiry codes on cartons | Bottle or pouch batch coding | Large box or bag printing | Scan-grade box barcoding | Inline film coding (VFFS/HFFS) | Logistics label automation | Permanent branding and traceability |

| Permanence of Mark | Moderate | Moderate | Low to moderate | Moderate | Moderate (resin = high) | High (label-based) | Very High (engraved/etched) |

| Application Type | TIJ | CIJ | DOD | HRIJ | TTO | LPA | Laser |

|---|---|---|---|---|---|---|---|

| Carton coding | ✅ | ✅ | ✅ | ✅✅ | ❌ | ✅✅ | ✅ |

| Bottle/can coding | ❌ | ✅✅ | ❌ | ❌ | ❌ | ❌ | ✅✅ |

| Cable/pipe extrusion | ❌ | ✅✅ | ✅ | ❌ | ❌ | ❌ | ✅✅ |

| Pallet/secondary packaging | ❌ | ✅ | ✅✅ | ✅ | ❌ | ✅✅ | ✅ |

| Flexible packaging film (flow wrap, pouches) | ❌ | ❌ | ❌ | ❌ | ✅✅ | ❌ | ✅ |

| Retail box branding | ❌ | ❌ | ❌ | ✅✅ | ❌ | ✅ | ✅✅ |

| Pharma/serialization compliance | ✅ | ✅ | ❌ | ✅✅ | ✅ | ✅ | ✅✅ |

| High-speed printing (300+m/min) | ❌ | ✅✅ | ❌ | ❌ | ✅ | ❌ | ✅ |

| Label-based logistics/tracking | ❌ | ❌ | ❌ | ❌ | ❌ | ✅✅ | ❌ |

| On-film date/lot/batch printing | ❌ | ❌ | ❌ | ❌ | ✅✅ | ❌ | ✅ |

| Permanent/anti-counterfeit coding | ❌ | ❌ | ❌ | ❌ | ❌ | ❌ | ✅✅ |

✅ = Suitable ✅✅ = Ideal ❌ = Not Recommended

| If You Need… | Choose… | Why It Works |

|---|---|---|

| Clean, sharp printing on cartons with minimal maintenance | TIJ / HRIJ | High-resolution, cartridge-based, easy to deploy |

| Ultra-fast printing on bottles, pouches, or cables | CIJ | Best for high-speed, curved or wet surfaces |

| Bold, large codes on corrugated boxes or chemical bags | DOD | Reliable valve-jet technology for porous, large substrates |

| Barcode-level clarity with logos or complex data on cases | HRIJ | High DPI + bulk ink + modular expansion |

| On-film date/batch code printing inline with packaging film | TTO | Ribbon-based precision for flexible packaging |

| Variable labels applied automatically during order flow | LPA | Real-time print + apply with WMS/ERP integration |

| Permanent, tamper-proof, and ink-free product identification | Laser | Zero consumables, no fading, suitable for regulatory traceability |

There is no single “best” technology — the right solution depends on your production speed, substrate, durability needs, and traceability requirements.

Use TIJ or HRIJ for carton-level clarity and barcode compliance

Use CIJ for fast, versatile coding on bottles and plastic

Use TTO for flexible packaging with high-speed film lines

Use DOD when marking large, rugged packaging in dusty environments

Use LPA when labeling must be precise, traceable, and automated

Use Laser for permanent, ink-free, and maintenance-light operations

✅ Work with a trusted integrator or technology advisor to match your operational needs with the right coding solution.

Each printing technology excels in different areas. There is no one-size-fits-all — selection should be based on:

Your substrate type (e.g., porous vs. non-porous)

Line speed requirements

Regulatory marking needs

Desired permanence of the code

Total cost of ownership (TCO)

Integration complexity

Ready to Find the Right Coding Solution for Your Line?

Ready to Find the Right Coding Solution for Your Line?Let our experts help you choose the optimal marking system for your materials, speed, and compliance needs — from inkjet to laser, from cartons to cables.

Contact us today!

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right machine you want.

Each printing technology requires its own type of consumables — whether it’s ink, ribbon, labels, or none at all. Understanding the right consumable for each system is critical to maintaining print quality, optimizing costs, and ensuring regulatory compliance.

Main Consumables:

Integrated ink cartridges (ink + printhead in one unit)

Ink Types Available:

Water-based inks – for porous materials like paper and cartons

Solvent-based inks – for coated cartons, films, foils, and plastics

Fast-dry inks – for high-speed lines

UV-curable inks – optional, for special substrates

Security/UV-visible inks – for anti-counterfeit coding

Common Brands Supported: HP®, Funai®, Collins®, Kao®

Replacement Cycle: Cartridge replacement typically every 300,000 to 600,000 prints depending on DPI and content.

Main Consumables:

Ink (dye or pigmented)

Make-up solvent (to maintain viscosity)

Filters (for pump, ink circuit, and air systems)

Ink Characteristics:

Fast-drying

Solvent-based (MEK, acetone, ethanol)

Excellent adhesion on plastics, glass, metal

Food-grade options available

Additional Items:

Cleaning solutions for flushing and maintenance

Service kits including filters and O-rings (interval-based)

Shelf Life: Typically 12–18 months for fluids in sealed containers.

Main Consumables:

Valve jet or piezo ink (bulk containers, usually 500ml–5L)

Ink Types:

Oil-based inks – for porous substrates (e.g., kraft boxes)

Water-based inks – for absorbent materials

Pigmented inks – for high-contrast marking

UV-resistant inks – for outdoor or export packaging

Ink Container Formats:

Refillable tanks or bulk bottle systems

Some systems support multiple colors (black, red, blue)

Maintenance Needs:

Minimal, but nozzle cleaning may be required depending on ink type

Main Consumables:

Oil-based ink (porous materials)

Solvent-based ink (coated boxes, films)

UV-curable ink (specialty substrates)

Bulk ink tanks (from 500 ml up to 1 liter)

Ink supply modules for larger production runs

Ink Properties:

High optical density

Designed for barcodes and scan-grade prints

Anti-clogging formulas for extended uptime

Printhead Cleaning:

Often automatic purge and wipe mechanisms included

Main Consumables:

Blank label rolls (thermal or thermal transfer)

Thermal transfer ribbons (for long-lasting prints)

Direct thermal labels (for short-term applications)

Label Formats:

Die-cut labels in various sizes (25mm–170mm widths)

Paper, PET, PP, PE label faces

Permanent or removable adhesives

Ribbon Types:

Wax – economical, for paper labels

Wax-resin – balanced durability and sharpness

Resin – durable, chemical and heat resistant

Print Durability:

Up to 10 years (resin on PET)

Main Consumables:

✅ None required for marking.

Optional Add-ons (Environmental Needs):

Fume extraction units (filter cartridges need replacement)

Protective glass windows (occasional cleaning/replacement)

Air filters in IP-rated enclosures

Cost Efficiency:

Highest long-term ROI due to zero ink, zero label, zero ribbon

TTO (Thermal Transfer Overprinter) – Ribbon Rolls

TTO (Thermal Transfer Overprinter) – Ribbon RollsMain Consumables:

Thermal transfer ribbon rolls (used to transfer print via heated printhead)

Ribbon Types:

Wax-resin ribbons – for general flexible packaging (e.g., snack films)

Full resin ribbons – for tougher substrates or sterilizable pouches

FDA-approved food-grade ribbons – for indirect contact with food packs

Ribbon Widths Available:

Typically 33 mm and 55 mm depending on printhead size

Lengths up to 1200 meters

Substrate Compatibility:

Flexible films (BOPP, PET, PE), foils, labels, laminated pouches

Common in vertical & horizontal form-fill-seal (VFFS / HFFS) machines

Ribbon-Saving Features:

Many TTO systems include gap-saving modes to reduce ribbon usage by 30–60%

Intermittent and continuous modes supported

Maintenance Needs:

Very low. Occasional printhead cleaning and roller inspection

| Consideration | What to Ask | Recommended Consumable Type | Typical Printer Types / Models |

|---|---|---|---|

| Substrate Type | Is the material porous, semi-porous, or non-porous? | Water-based ink / oil ink / solvent / UV / resin ribbon | TIJ (e.g., HP-based); DOD (porous); CIJ (film/plastic); TTO (film); HRIJ (boxes); LPA (labels) |

| Print Durability | Should the mark resist water, abrasion, or chemicals? | Solvent-based ink, UV ink, resin ribbons, laser | CIJ (industrial MEK inks); TTO (resin ribbons); Laser (no consumable, permanent); UV inkjet |

| Surface Sensitivity | Is the surface heat-sensitive or coated? | UV-curable ink, wax-resin ribbon, low-temp lasers | TTO (low-temp ribbons); UV laser; UV HRIJ; TIJ solvent inks |

| Speed of Production | Is the line operating at 300+ m/min or intermittent speed? | Fast-drying solvent ink / quick-transfer ribbons | CIJ (high-speed); TTO (continuous or intermittent); TIJ (medium speed); DOD (slow–medium) |

| Data Complexity | Is variable data, 2D code, or barcode required? | High-DPI inks, scan-grade ribbons, data-driven labels | HRIJ (barcodes); TIJ (QR codes); TTO (date/lot); LPA (shipping labels) |

| Labeling vs Direct Print | Do you need direct on-box marking or printed label application? | Label rolls, resin ribbons vs. bulk ink | LPA (logistics); TTO (flow-wrap); CIJ/TIJ/DOD/HRIJ (direct coding) |

| Environmental Conditions | Is the environment dusty, cold, humid, or high-temperature? | Sealed cartridges, pigmented inks, IP-rated enclosures | DOD (harsh); CIJ (condensation); TIJ (sealed); Laser (IP65) |

| Print Area & Coverage | Is the required mark large, small, or over multiple lines? | Multi-head ink modules / wide-format ribbon / labels | DOD (large char); HRIJ (stacked printheads); LPA (170mm width); TTO (53×75 mm max) |

TIJ → Uses sealed ink cartridges; best with water- or solvent-based inks

CIJ → Requires ink + make-up solvent; ideal for curved and high-speed surfaces

DOD → Bulk oil-based ink; great for bold, large text on porous boxes

HRIJ → High-DPI ink for scan-grade barcodes; supports bulk or cartridge systems

TTO → Ribbon only (no ink); width and formulation depend on machine model (e.g., 33mm for 6230, 55mm for 6330)

LPA → Label rolls + ribbons (TT); labels must match applicator specs (gap, sensor, rewind direction)

Laser → No ink or ribbon; only optional lens protection, filter kits, and safety enclosures

Our inks are formulated to meet the strictest demands of modern production environments. Whether you’re coding on plastic, glass, metal, film, or paper, we provide optimized solutions with fast drying, excellent adhesion, and resistance to smudging, alcohol, or migration.

Standard Dye-Based Ink

Ideal for everyday use across most porous and non-porous materials. Fast drying and cost-effective.

Alcohol-Resistant Ink

Specially formulated for applications where the printed code may be exposed to ethanol or alcohol-based disinfectants — ideal for pharmaceutical, cosmetic, and sanitary industries.

Non-Migration Ink

Designed for food and medical packaging where contact with product is a concern. These inks ensure compliance with regulatory guidelines on ink migration.

High-Adhesion Ink

Perfect for difficult substrates like PVC, rubber, or oily metals. This ink resists flaking or fading even on low surface energy materials.

UV-Visible and Invisible Inks

Ideal for security coding, anti-counterfeiting, or internal traceability applications.

Black (most common, with high contrast and durability)

White (for dark or transparent surfaces)

Yellow (excellent for visibility on darker packaging)

Red and Blue (used for product differentiation, branding, or special notices)

Custom colors available upon request

Our make-up (solvent) fluids are engineered to maintain ink performance, viscosity, and print quality. Cleaning solutions are essential for flushing nozzles and maintaining system cleanliness.

Make-Up Fluids: Matched by formulation to our inks for stable print quality.

Cleaning Solutions: Available in standard and aggressive formulations, compatible with various printhead materials and ink types.

We ensure compatibility with brands such as Videojet, Domino, Linx, Willett, Hitachi, Citronix, and more.

.png)

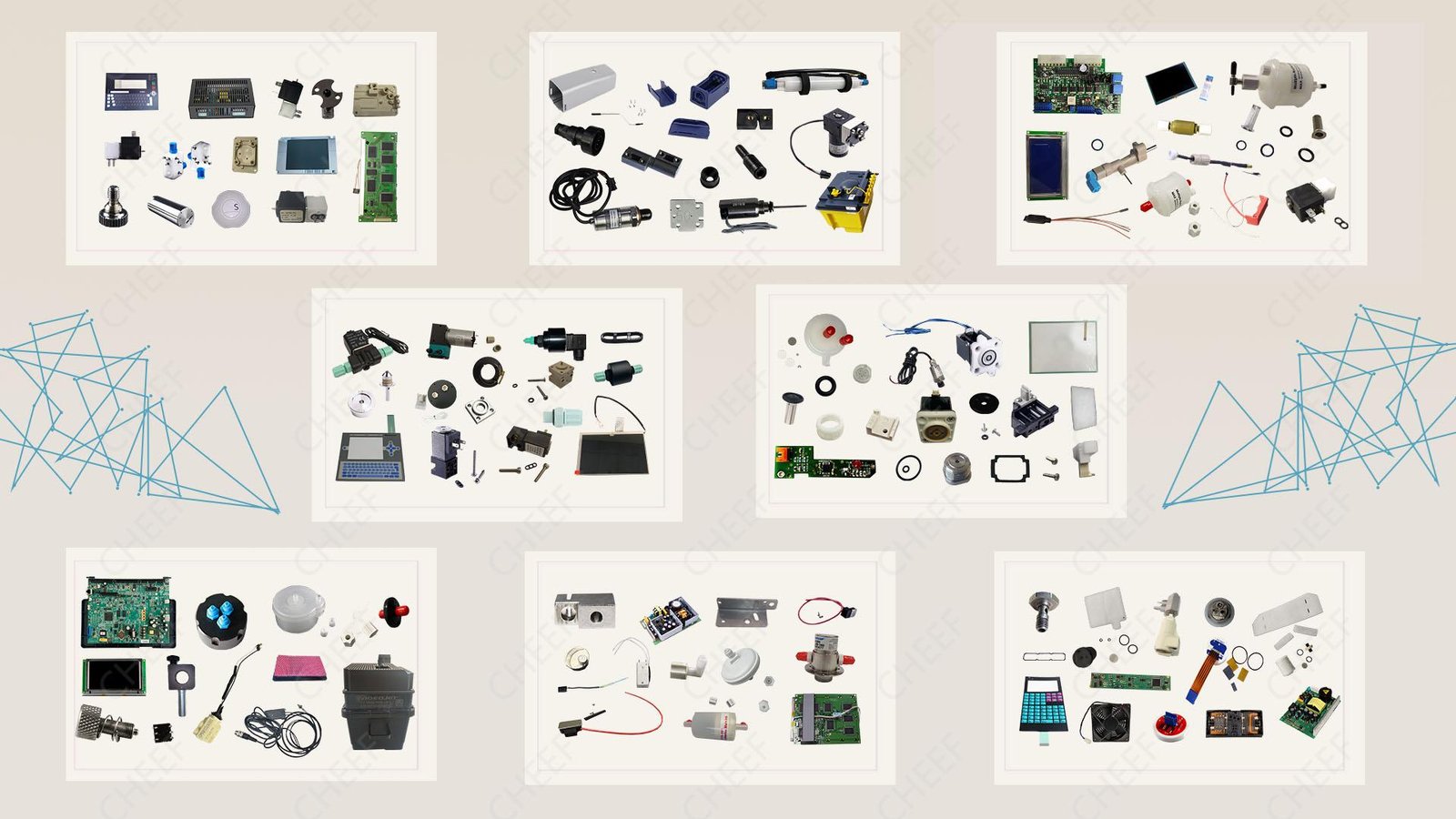

CIJ printers are composed of multiple modular components. These parts ensure consistent ink circulation, stable high-speed printing, and reliable performance under 24/7 production environments.

Printhead modules (40μm, 50μm, 60μm, 70μm) – For different droplet sizes and speed/quality balance

Valve modules – Control ink nozzle pressure and droplet formation

Mainboard (MCB) & I/O Board (PIB) – Central processing & peripheral signal input

Power Supply Unit (PSU) – Stable voltage supply and power distribution

High-voltage transformer – For charging the ink stream

Control panel / LCD / Keypad – Operator interface

Ink core module (with/without pump) – The core ink circuit, including filters and pumps

Ink & solvent pumps – Regulate internal circulation and viscosity

Ink reservoir (CSB/ink door assembly) – Houses ink chamber, tubing, and valves

Return pump & recycle valve – Responsible for ink recovery and pressure stabilization

2m / 3m / 6m Umbilical hose assemblies – Connect controller to printhead

Available in multiple versions (with/without head modules; standard or mesh)

Service modules 1 & 2 – Pre-configured assemblies for field maintenance

Printhead covers / nozzle shields – Protect nozzle from dust and back pressure

Positive air pressure pump – Keeps dust/moisture away from nozzle

Air drying unit – For moisture-sensitive environments

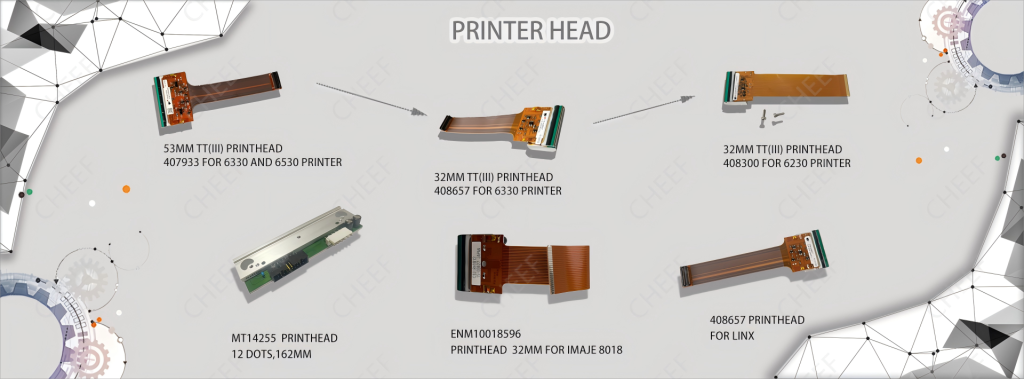

TTO printers involve mechanical precision, ribbon motion control, and thermal printhead coordination. Accessories are often size-specific (e.g., 32mm, 53mm, 107mm).

Printheads (32mm / 53mm / 107mm) – With dedicated PCB per width

Printhead return springs (short & long) – Maintain pressure balance

Printhead bracket kits (right/left-hand, size-specific)

Print modules (print body) – Full assemblies that house the head and mechanics

Stepper motors – For printhead positioning and ribbon drive

Ribbon cassettes (size-specific) – Interchangeable quick-load units

Ribbon supply & take-up spools (black/silver color-coded)

Drive motors (with/without synchronizer) – Control ribbon motion

Peel rollers & white feed rollers – Maintain ribbon path integrity

Tension springs, shafts, blade springs – Mechanical regulation of ribbon flow

Linear guide rails / sliders – Allow smooth, precise printhead movement

Cylinders & solenoids – For pneumatic tamp or retract motion

Synchronous belts & pulleys – Drive synchronization between ribbon and packaging film

Air regulators & valves – Maintain air pressure for print actuation

Controller PCBs / Power Supply Units (PSU) – Central logic and power regulation

Memory cards – Store templates, logs, or firmware

Status indicator modules – Visual operation feedback

Display screens – For user input and job control

Photoelectric sensors (emitter + receiver) – For ribbon positioning or film detection

Label mark / film gap detectors – Ensure accurate ribbon start

Light curtains / enclosure kits (optional) – For operator protection

Cartridge printheads (Blue / Red / Green / Gold)

Controller modules (M610, 8510, 8520, Touch & OEM versions)

Touchscreen displays & power supplies

Straight data cables (1m / 3m / 5m)

I/O cables (3m / 5m)

Mounting frames (25×25 mm aluminum pipe, 400mm/600mm arms)

Cross clamps / flange clamps – for stable head mounting

Synchronization kits – encoder wheels, 8-pin cables

Parallel linkage kits – for precise head movement

Serial port cables (RS232) – optional for OEM use

707 / 716 / 807 / 816 printheads

1L & 5L ink system modules (porous / non-porous)

Filter sets, pressure regulators, tubing kits

Low ink level detection harnesses

Alarm beacon assemblies

Product sensors & encoder kits

Master/slave connection boxes (for multi-head sync)

Nozzle kits (20mm / 25mm / 32mm / 48mm)

Printhead enclosures

Ink throttle valves & valve boards

Keypads (Simplified / Traditional Chinese)

LCD panels & cover assemblies

Controller enclosures (for harsh environments)

Internal & external cable assemblies

Power supplies with region-specific cords