The first is the recovery failure, check whether the ink line is deviated, that is, whether the line ejected by the nozzle is crooked. If it’s not crooked, it means it’s blocked here. Spray cleaner on the nozzle side, rinse it, blow dry, then turn it on again.

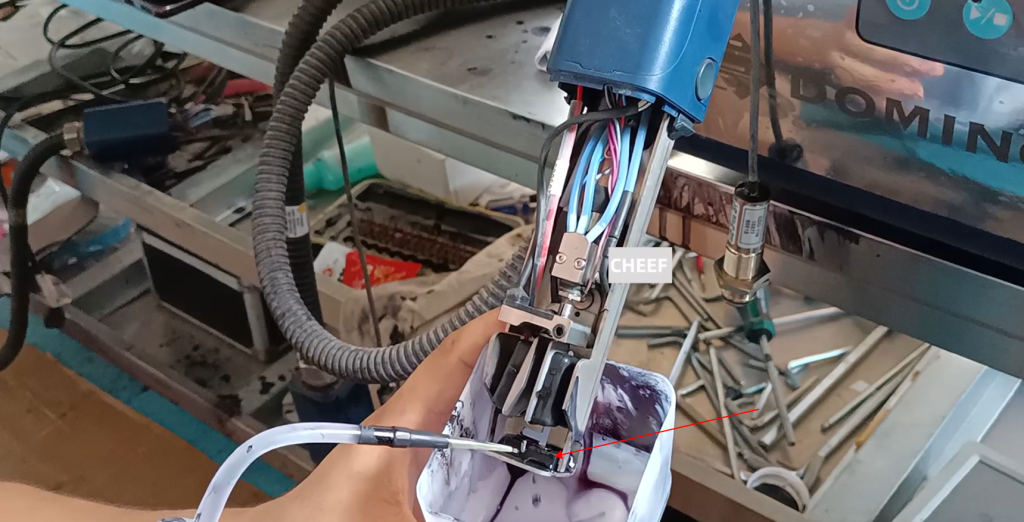

See if you can reach the correct location for our recycling chute. Generally speaking, it is most likely that the nozzle is blocked and the recovery tank is blocked. The premise is that the machine is used normally and the machine is switched on and off normally:

There is also a high-voltage fault. First of all, look at the high-voltage sheet plate to see if there is ink accumulation or moisture:

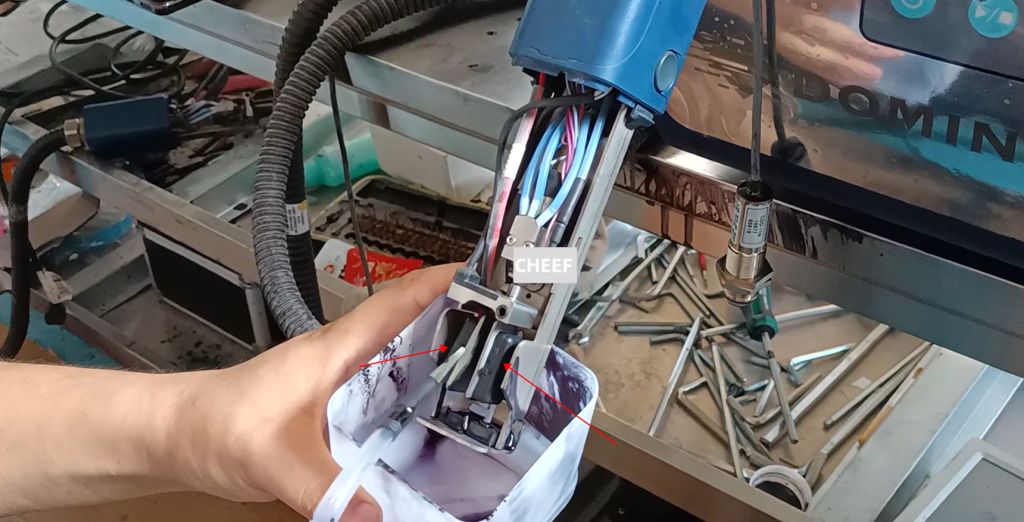

Or there is a large amount of dry ink on the recycling tank. If there is any, clean it and dry it, and then turn it on again. The general problem can be solved:

There is also an ink spot detection fault. There is ink on the charging slot. For these two faults, first check the gap in the charging slot to see if there is ink in it. If there is ink, clean it and blow dry. All faults are based on the correct parameters. The following is when the viscosity and pressure are normal:

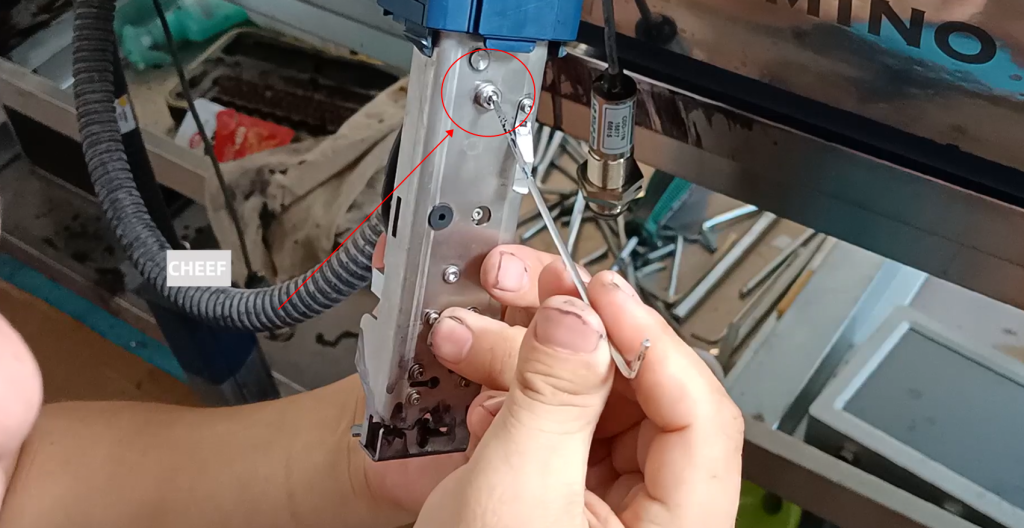

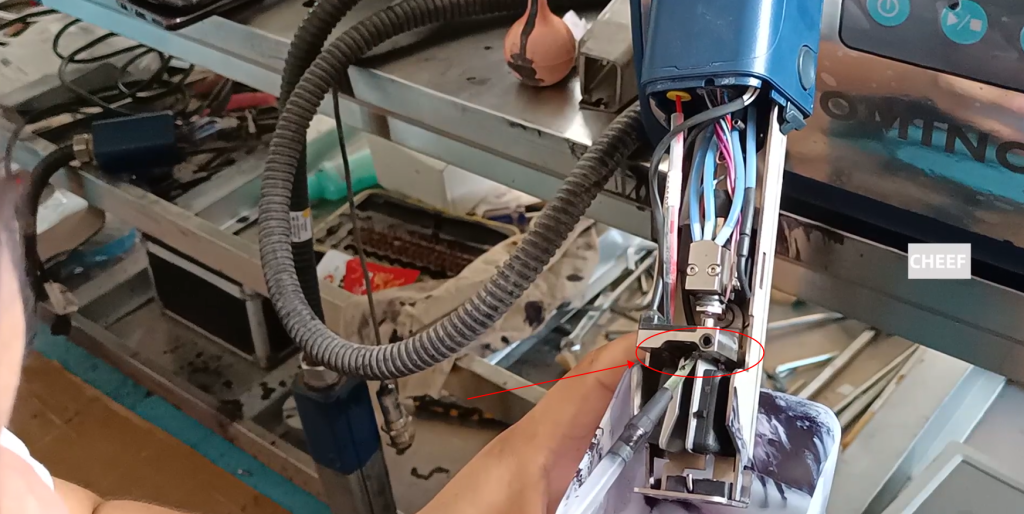

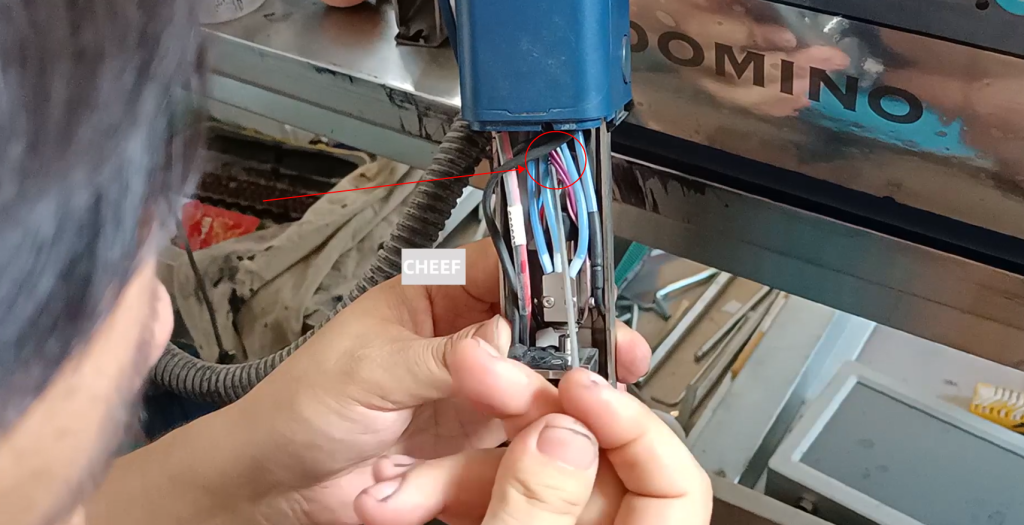

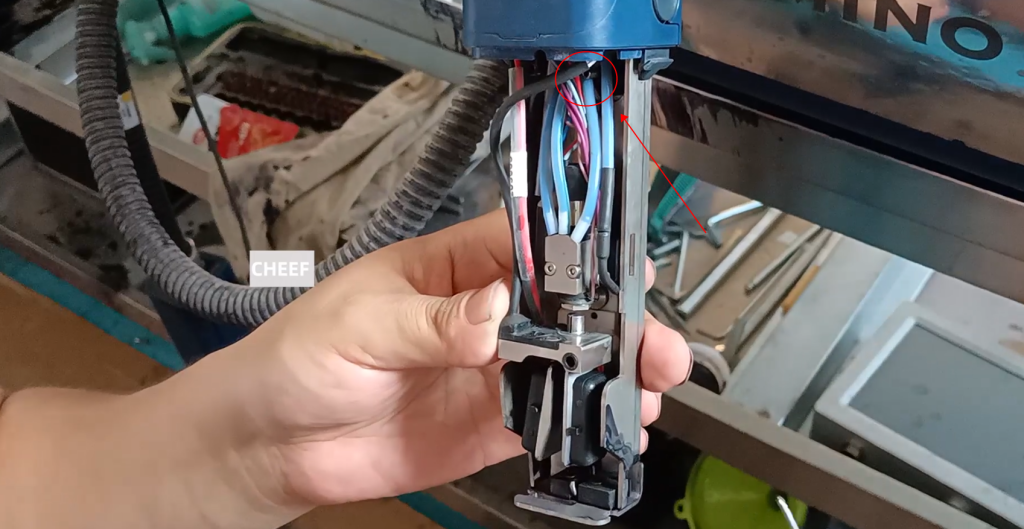

When the ink line is biased and needs to be adjusted, it can be divided into front and rear and left and right. Whether it is to adjust left and right or front and rear, be sure to loosen this screw first:

If we adjust left and right, we need to loosen this screw, and if we adjust this, the nozzle will swing left and right:

Before and after the adjustment is to loosen the screw. This is equivalent to the front and rear of the ink line. After the ink line is adjusted, tighten the fixing screw: