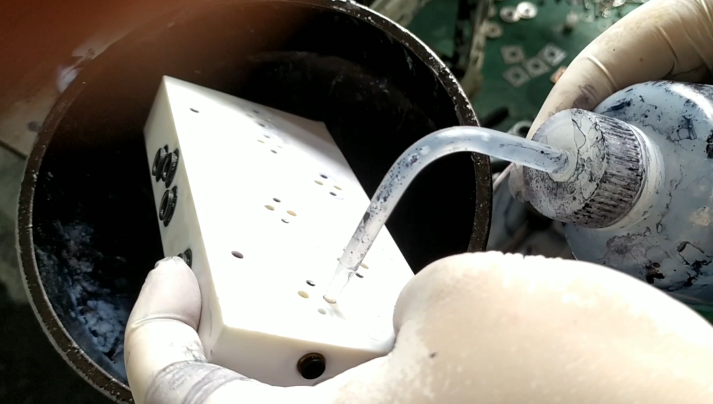

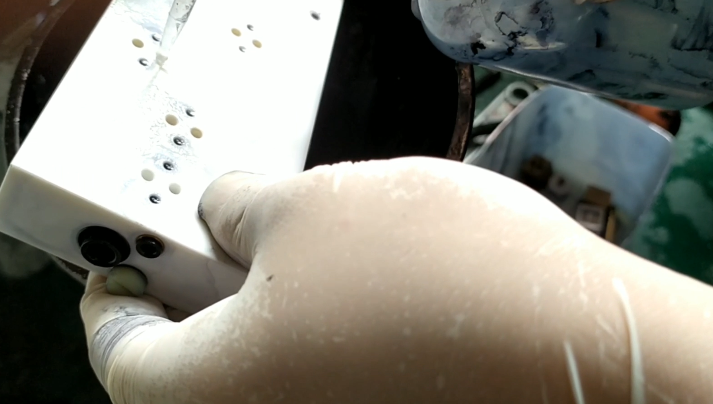

Let’s assemble the ink shunt block. First, we clean the ink shunt block with cleaning fluid. We have to check whether each hole is unblocked. If the machine is not used for a long time, that is to say, it has been placed for a year or half a year, and then it is not used, we will remove all its accessories, and then replace all the pipes with new ones, which will be more stable.

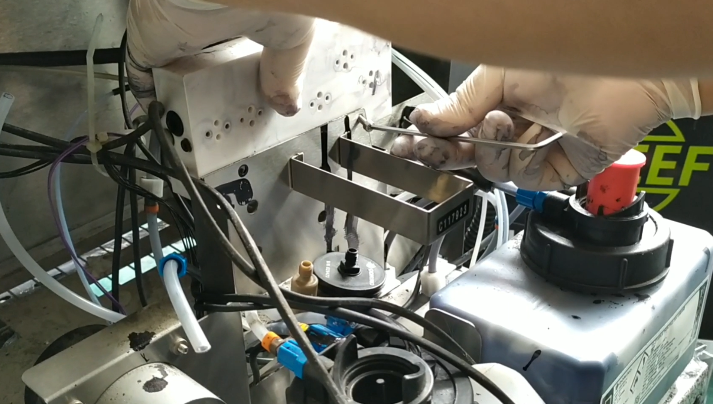

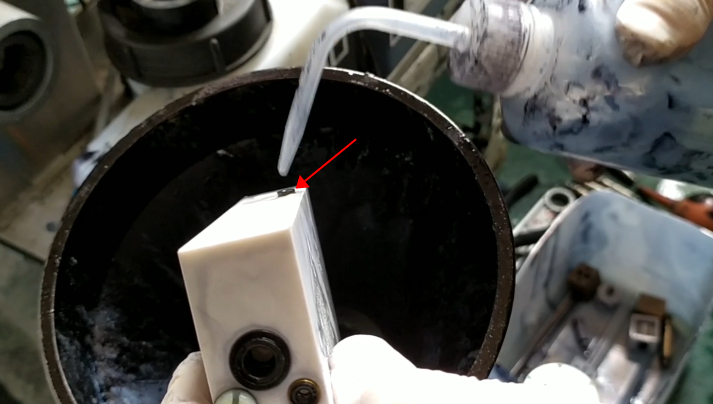

Now the white module has been soaked for about one or two days, and then we install it now. We use the cleaning pot to check whether each hole is unobstructed:

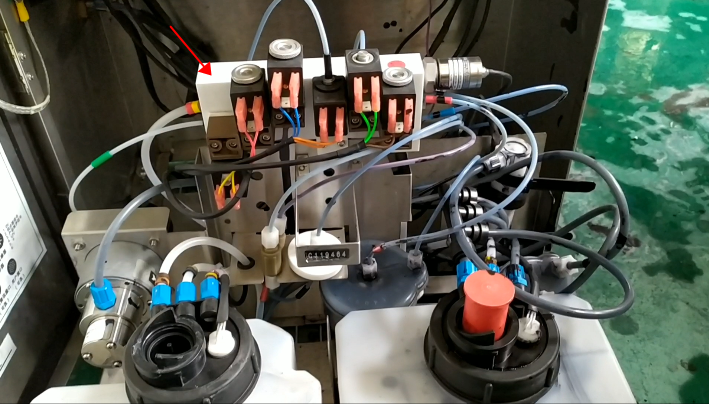

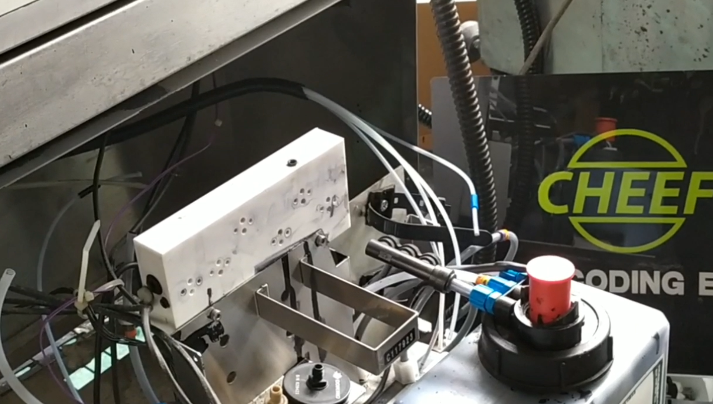

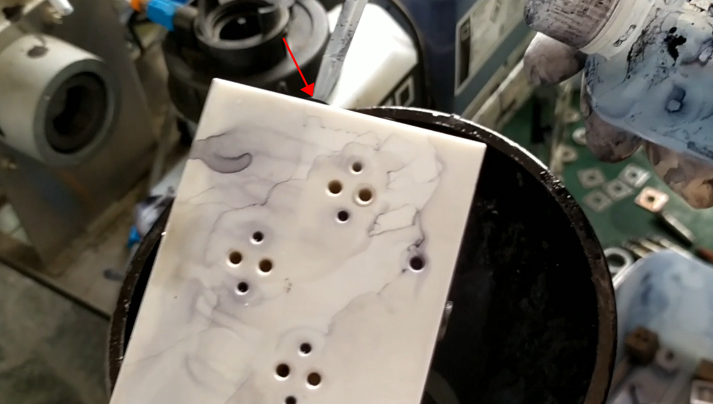

This is the ink diversion block. Solenoid valve and pipe have been inserted on it: